Pure Dairy evolved from a business model innovation project to drive adoption of packaged milk among raw milk consumers. It started as a pilot venture to market test long life milk produced using a custom manufacturing setup and sold via retail and direct channels.

The venture also piloted a disruptive model to bring raw milk directly from farm to consumer using a custom designed EV based milk vending and packaging setup. Pure Dairy then evolved to become a partner to the best known private dairy brand in UP.

At the outset of our journey, 86% of the milk and dairy market in North India remained unorganized. Even prominent national and regional dairy brands struggled to make meaningful inroads. Consumers had a deep – rooted preference for unpackaged milk, and our challenge was to uncover if – and where – there was space for packaged alternatives to earn trust and gain traction.

An extensive market study – spanning hundreds of interviews, field immersions, and ethnographic research across the diverse landscapes of Uttar Pradesh and Madhya Pradesh – uncovered deep insights into the dynamics of milk production, distribution, and consumer behavior.

Applying the principles of Jobs To Be Done and Ecosystem Innovation, these insights shaped a new business model. This model was brought to life through the design and launch of an innovation-led pilot venture: Pure Dairy.

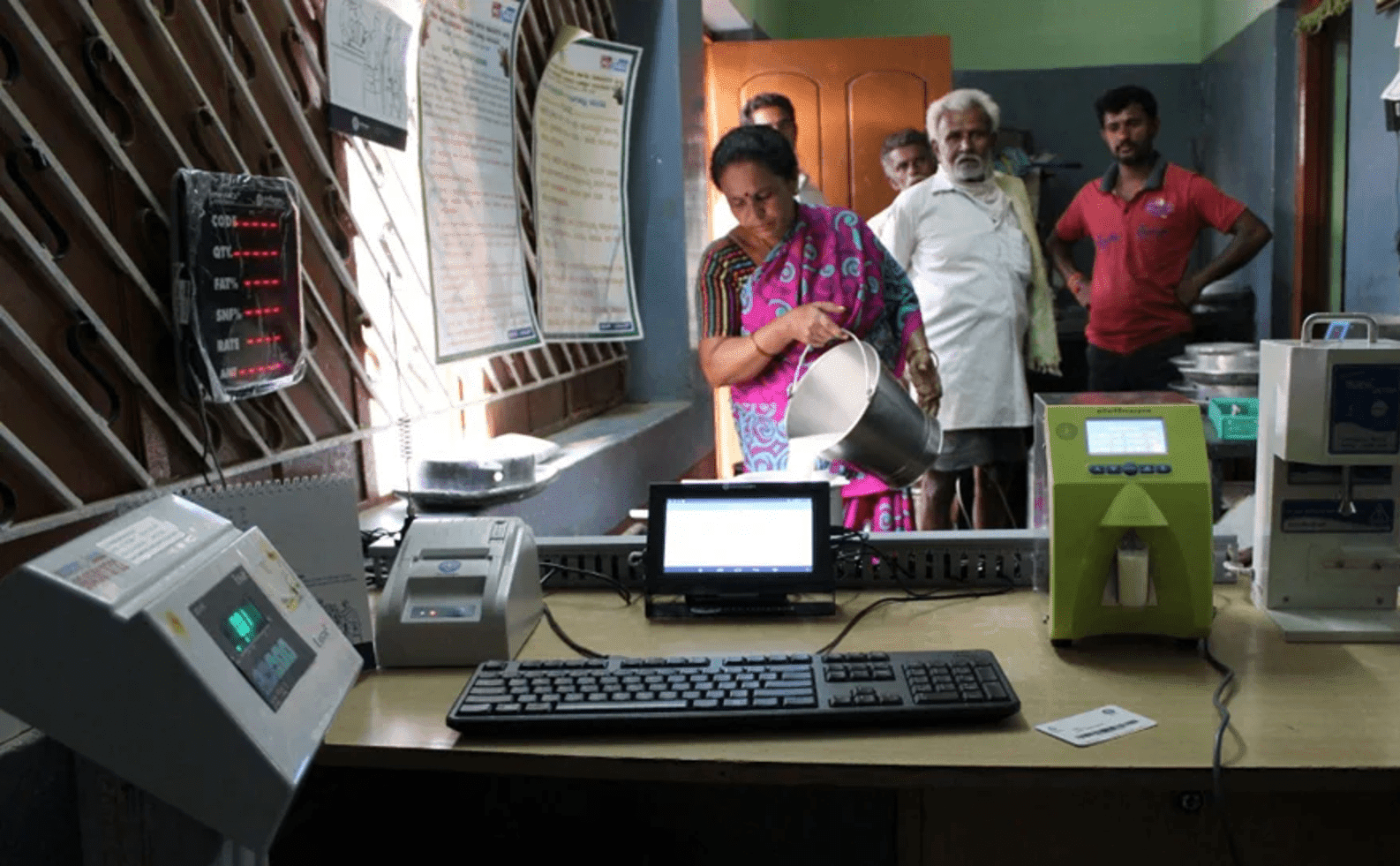

As a pilot venture, Pure Dairy was designed to test and refine the critical success factors for packaged milk in a traditionally unorganized market. This included validating the business model, village – level procurement, plant design, processing technologies, product attributes, packaging formats, retail placement, and pricing structures.

Leveraging a proprietary framework for testing critical assumptions, the pilot identified and validated the elements that would define commercial viability. The initiative also involved iterative testing of technical components – ranging from processing and packaging systems to utilities, plant layout, and operational design – ensuring that both the business and technology elements were covered.

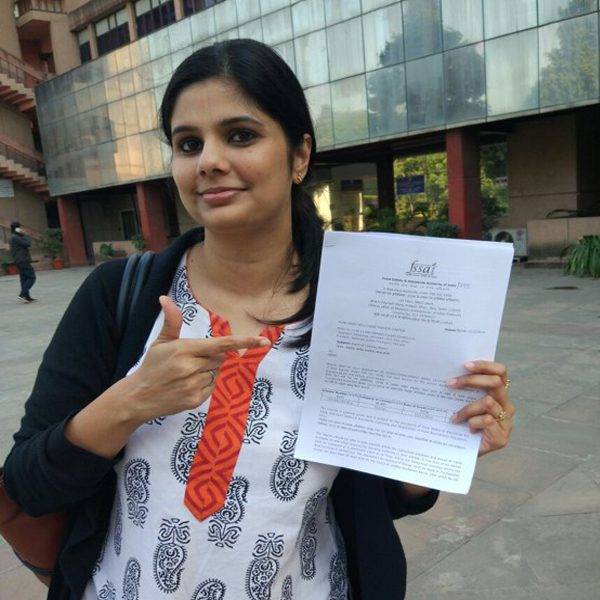

Our business model centered on a compact, decentralized dairy unit located near procurement hubs, designed to produce long-life milk in small batches – a concept with no existing precedent. This required us to build an end-to-end milk processing facility from the ground up, including regulatory approvals, operational processes and team formation.

In parallel, we established a complete supply chain for packaged milk – managing the flow of raw milk from farm to factory, and finished product from factory to consumer, through both distributor networks and direct retail channels. The entire operation was executed within a timeline that defied industry norms, setting a new benchmark for speed and agility.

The product was launched under the brand Malaika Milk – a name inspired by the word malai (cream), a widely recognized symbol of milk quality in Northern India. Processed to exacting standards, Malaika was offered in two long-life packaging formats with shelf lives of 45 and 90 days.

It quickly gained a loyal following in Eastern Uttar Pradesh, where discerning consumers praised its taste and freshness. In a market with minimal exposure to packaged milk, Malaika achieved daily sales of up to 5,000 liters – an impressive feat for a new entrant.

The pilot yielded valuable insights into seasonal product variation, milk type behavior, processing techniques, brand positioning, and pricing strategy. Like most pilots, it delivered a mix of standout successes and critical learnings that informed further product iteration and refinement.

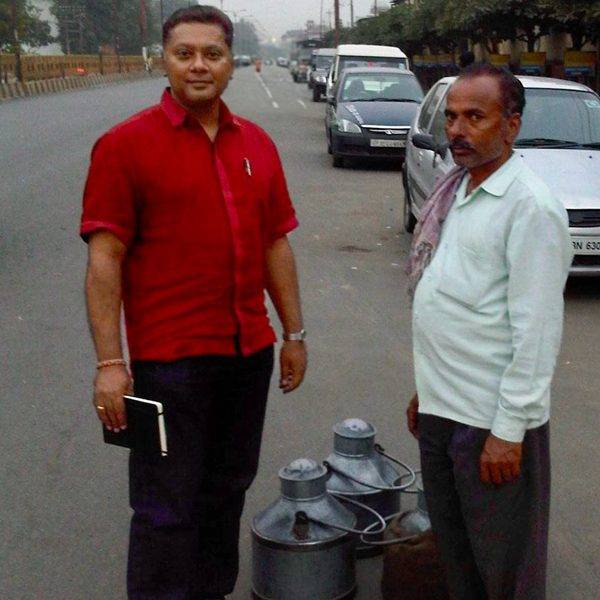

Recognizing the deep-rooted consumer preference for raw milk, Pure Dairy pursued a classic disruptive innovation strategy – bypassing traditional processing altogether to deliver milk directly from farm to consumer, with chilling as the only intermediate step.

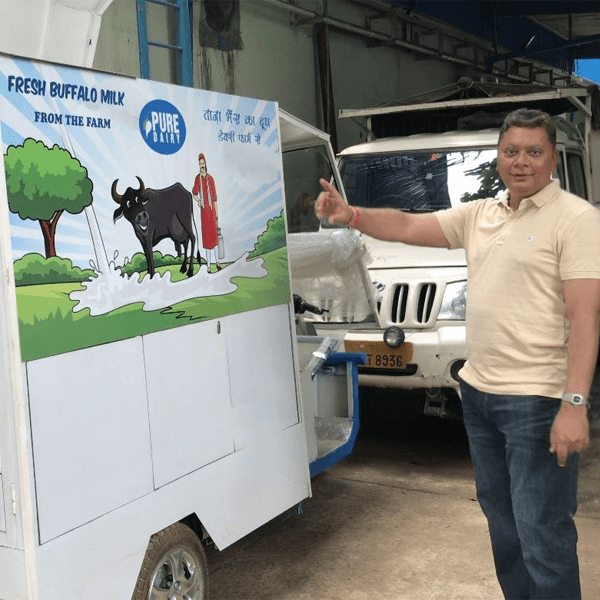

To enable last-mile delivery into narrow lanes and dense residential areas, custom-designed, light-footprint electric milk vans were developed from the ground up. Such a mobile unit transported raw, chilled milk directly to neighborhoods, offering two dispensing options: consumers could either fill their own containers or purchase milk packaged on-site using an integrated, on-board pouching system.

Amid the uncertainty of COVID-19 lockdowns and market disruption, Pure Dairy shifted focus toward commercial resilience

A pivotal move in this direction was forging a strategic partnership with Gyan Dairy – Uttar Pradesh’s most trusted and established dairy brand. For over three years, Pure Dairy managed all processing and packaging operations for Gyan’s key markets in Eastern UP and Bihar.

Despite the volatility of two pandemic waves, the venture ran profitably and without a single day of disruption – demonstrating operational excellence and resilience under pressure.

Following a successful partnership with Gyan Dairy, Pure Dairy transitioned its Varanasi operations to Moomark Private Limited, a wholly owned subsidiary of Stellapps. While this marks the close of one phase, it is the beginning of another. Staying true to its innovation-first mindset, Pure Dairy is now exploring new frontiers in dairy, food processing, and adjacent sectors – carrying forward the spirit of experimentation and impact.